Ventilation is essential for enclosed swimming pools and spa rooms for the following reasons:

- To prevent the enclosure becoming excessively humid;

- To eliminate or minimise condensation;

- To prevent the build-up of chloric acids, which are highly corrosive and potentially harmful;

- To ensure chlorine fumes and/or odours do not migrate to adjacent indoor areas;

- To maintain comfortable conditions for bathers.

BCA requirements for small indoor swimming pools

Where swimming pools are enclosed, the Building Code of Australia (BCA) requires natural ventilation complying with clause 4.6, or mechanical ventilation complying with AS1668.2 or AS/NZS 3666.1.

Australian Standard AS1668.2-2012 specifies a minimum flow rate per m² of floor area in APPENDIX B. These flow rates are listed below for their respective pool types:

- Spas and Hydrotherapy pools - 15l/s.m²

- General Pool and Deck areas - 10l/s.m²

It is important to note that these values are specified as a minimum only. In internal spaces where temperatures exceed 30°C or there is agitated water surfaces, it may require significantly higher hourly air change rates. For the purpose of minimising contaminant levels, AS1668.2-2012 also recommends that the intake side of the fan is positioned as close to the pool surface as practical.

Corrosion resistance to chlorine

The formation of chlorine-saturated condensation in pool enclosures creates an aggressive electrolyte that causes corrosion. Steel fan components suffer heavily from these types of conditions as do aluminum components such as impeller blades and inlet cones.

Epoxy-coated fans offer a degree of corrosion resistance against chlorine water however they are not suitable for the extraction of dry chlorine fumes. It is also important to note that chemical compatibility databases such as Cole-Parmer only list epoxy as satisfactory up to 22°C. For this reason Fantech recommend fans with a chlorinated rubber coating, a protective layer highly effective in resisting hypochlorous acid.

Appropriate ventilation solutions

The correct ventilation solution for a given pool enclosure depends on a number of variables — including the pool surface area, the enclosure volume and whether or not the area is sealed from adjacent rooms.

The required 10-15 l/s.m² of replacement air may be drawn from an adjoining room, however taking conditioned air from this room will significantly decrease the building’s energy efficiency during both winter and summer months. It is therefore recommended that the following two methods are considered:

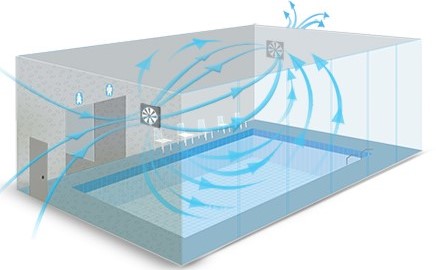

- Saturated air is exhausted via a roof/wall mounted fan(s) at, or above the specified minimum flow rate. A supply air fan positioned at the opposite end of the enclosure should replace the exhausted air at a flow rate no more than that of the exhaust air unit. This ensures that a slight negative pressure is maintained within the swimming pool enclosure.

- Alternatively, to minimise running costs, a supply air fan may be replaced with louvered fresh air openings allowing low velocity air to enter the pool enclosure. The fresh air openings should be positioned opposite the exhaust air unit(s) to prevent short circuiting and areas with stagnant air.

Air may be exhausted from a pool enclosure via roof, wall or window mounted fans.

Duct mounted fans are also suitable, providing the fan and surrounding duct work are treated to avoid accelerated corrosion. Roof mounted fans should have a vertical discharge to ensure all contaminants are ejected away from the building envelope. This also reduces the risk of roof cladding, fittings and other components adjacent to the discharge suffering from exposure to chlorine. For the same reason, wall and window mounted fans should not discharge directly onto surrounding structures.