Are JetVent fans “Deemed-to-Satisfy”?

To meet the 'Deemed-to-Satisfy' (DTS) requirements of the BCA, a car park ventilation system must comply with AS1668.2:2012 or an adequate system of permanent natural ventilation (Section F4.11) and AS/NZS1668.1:1998.

To date the only reference to the use of jet fans in the 'Deemed-to-Satisfy' provisions for car park ventilation is in clause 4.4.2(c) of AS/NZS1668.2:2012. It allows jet fans to assist with the ventilation of a ducted system in areas that are difficult or impractical to reach with ducting. In other words, using a single jet fan to move air from a dead spot can be made deemed-to-satisfy from a ventilation perspective. As soon as a jet fan moves air to another fan or jet fan, this would fall outside of this clause.

Clause 5.5 of AS/NZS1668.1:1998 only references supply and exhaust fans. This is because the standard was written before jet fans were introduced into Australian in 2005. As jet fans are not mentioned in the current standard they do not meet the deemed-to-satisfy provisions from a fire and smoke control perspective.

Therefore, an alternative solution showing compliance with the ventilation and fire/smoke control performance provisions of the BCA will be required for most JetVent fan projects.

Formulating an alternative solution

The most common method of proving compliance for JetVent fans is by performing an alternative solution. An Independent Statutory Body has agreed that the relevant performance requirements applicable to jet fans are FP4.4, EP1.4, and EP2.2 of BCA2013 (where jet fans are outside the Deemed-to-Satisfy requirements).

BCA2013 FP4.4

A mechanical air-handling system installed in a building must control:

- The circulation of objectionable odours; and

- The accumulation of harmful contamination by micro-organisms, pathogens and toxins.

The most comprehensive way of demonstrating this is by producing a Computational Fluid Dynamics (CFD) model of the car park. The model has to simulate pollution and air flow movement within the car park to ensure that carbon monoxide (CO) levels meet the requirements outlined in BCA2013 FP4.4. This approach may be unnecessary for smaller car parks and those partially served by natural ventilation. In these cases, ‘expert judgment’ (or knowledge gained from projects completed previously) may indicate that a proposed car park ventilation design using JetVent fans will be adequate.

In order for the JetVent fan ventilation system to be approved as an alternative design solution under AS1668.2:2012, it will need to be demonstrated that CO concentration levels between 900mm and 2500mm above the floor are limited to:

- 60ppm 1hr maximum average

- 100ppm peak value; and

- 30ppm Time-Weighted Average (TWA) over 8hrs

The 60 ppm 1hr maximum average is taken to be the significant design criteria because this assumes peak CO concentrations do not exceed 100 ppm (as detailed in Section J5 of AS1668.2 2012). The 30 ppm time weighted average is rarely used as it applies to car parks where people work within the confines of the car park without having separate ventilation systems for their work area (eg. car parks with a car wash inside or parking attendant booths with no other sources of ventilation).

BCA2013 EP1.4

An automatic fire suppression system must be installed to the degree necessary to facilitate control of the development and spread of fire appropriate to:

- The size of the fire compartment;

- The function or use of the building;

- The fire hazard;

- The height of the building.

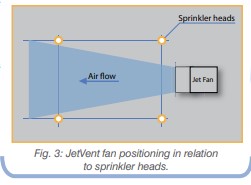

In order to comply with performance requirement EP1.4, JetVent fans should be located in-between sprinkler heads as per Figure 3. A CFD analysis may be required to show that the difference in sprinkler activation times between JetVent fans running at full design speed and switched off is negligible. Fast response sprinkler heads can be a good option to further improve safety.

It should also be shown that the air velocities at the sprinkler head positions are minimal.

BCA2013 EP2.2

a) In the event of a fire in a building the conditions in any evacuation route must be maintained for the period of time occupants take to evacuate the part of the building so that:

- The temperature will not endanger human life: and

- The level of visibility will enable the evacuation route to be determined; and

- The level of toxicity will not endanger human life

b) The period of time occupants take to evacuate referred to in (a) must be appropriate to:

- The number, mobility, and other characteristics of the occupants; and

- The function or use of the building; and

- The travel distance and other characteristics of the building; and

- The fire load; and

- The potential fire intensity; and

- The fire hazard; and

- Any active fire safety systems installed in the building; and

- Fire brigade intervention.

The fire engineer should discuss with the local authorities how compliance with EP2.2 will be achieved as requirements can vary depending on project location. If a system containing JetVent fans was shown to be at least equivalent to the Deemed to Satisfy provisions during occupant evacuation, then Performance Requirement EP2.2 could be met according to Clause A0.5 of BCA 2013.

Alternatively if it can be shown that the conditions in any evacuation route are maintained for the period of time occupants take to evacuate, this would also show compliance with EP2.2.

A CFD analysis may be performed to demonstrate compliance with either of the above requirements.

Is Additional Detection Required?

When jet fans are shut down, tests have shown that smoke layers reform improving visibility. It is therefore desirable to shut down JetVent fans on the detection of a fire (typically through the sprinkler system).

Fantech suggests that JetVent fans should be placed in the driveways of a car park as fires are most likely to occur in the car parking bays. The risk of affecting sprinkler operation would be reduced as the JetVent fans would then be positioned away from the fire affected sprinkler heads.

To cover the unlikely event that a fire occurs directly in front of a JetVent fan, an additional fire or smoke detection device is required. Fantech can offer an integrated duct probe smoke detection solution to meet this condition.

What does my Fire Engineer need to do?

At the start of the design process the Fire Engineer should add JetVent fans to the alternative solutions in the Engineering Brief and meet with the appropriate Fire Brigade to discuss. The purpose of the Fire Engineering Brief is to table all alternative solutions with the approval authority (in most cases the Fire Brigade) and to obtain approval with any conditions that may need to be addressed.

This will give design certainty for the project and ensure that all parties are aware of the steps that will need to be taken.

For more information regarding JetVent fans please contact your local Fantech office.