What sort of fan motor do I need for my spray painting booth?

This type of question often confronts our sales engineers. While this appears to be a straightforward request, a spray booth could be classified as a hazardous area because:

- An explosive atmosphere is (or is likely to be) present and,

- It may require special precautions for the construction, installation and use of potential ignition sources (which would be a fan in this example).

As it can be classified as a hazardous area, we require specific information to make the correct selection.

Ref: AS/NZS 60079.0:2012

An explosive atmosphere can contain liquid, gas, or dust. Flammable liquids are easily identified as such by warning labels on the product; however some hazardous applications are not as obvious. A sewerage plant for example contains gases that could be explosive, while a wheat silo or flour mill can contain dusts that are latent, but highly explosive.

The above two applications would require different types of hazardous motors and selecting the correct one is imperative as the wrong motor could have disastrous results.

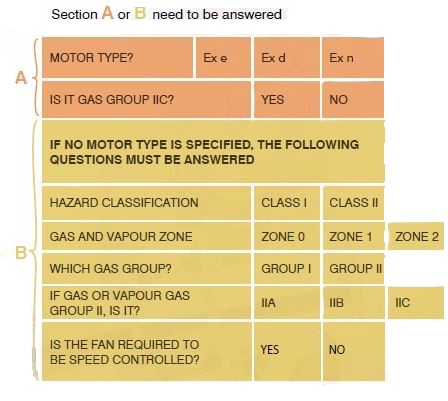

It is therefore critical that accurate information is supplied so that the correct fan/motor can be selected. An example of the required information for a gas/vapour hazard is shown in the image below.

If a fan for a hazardous area is required, we need to know the motor type required - Ex n, Ex e or Ex d? We also need to know if Gas Group IIC is present so we can be sure the appropriate cable gland is fitted to the motor. Providing this information will ensure the correct motor is selected.

When gas is the explosive atmosphere within a hazardous area, the following information is required:

Hazard Classification

Class I - Indicates that it is a hazardous gas or vapour.

Class II - indicates that the hazardous material is dust or fine fibre.

Gas and Vapour Zones (for Class I)

Zone 0 - Indicates that the flammable substance may be present during normal operation of the equipment.

Zone 1 - indicates that the flammable substance may be present in the vicinity of the equipment for short periods of time.

Zone 2 - indicates that the flammable material will not be present during the normal operation of the equipment and if it does, it will exist for a short period of time only.

Gas Group

Group I - Mining (methane)

Group II - Surface industries

Group III - Dusts and fibres

Gas and Vapour Gas Group (for Group II)

IIA - eg. Propane

IIB - eg. Ethylene

IIC - eg. Hydrogen

(The above gases listed are typical, with IIC being the most severe)

| Motor type (CMG) |

Ex n |

Ex e |

Ex d |

| Class |

I |

I |

I |

| Zone |

2 |

1 |

1 |

| Gas Groups |

IIA, IIB, IIC |

IIA, IIB, IIC |

IIA, IIB |

| Speed Controllable? |

No |

No |

Yes |

*Example of typical hazardous limitations of motors handling gases*

*Please note that these are only examples and Fantech can assist in determining if the motor will comply with the above information. Any hazardous motor should have a test report available which will detail the limitations of use.

An example of this is as follows. If we had a Class I, Zone 1 application with Gas Group IIB, and the motor needed to be speed controlled, we would need to select an Ex d motor from the above CMG range.

Fantech has a very rigorous procedure in place to ensure hazardous location fans are built to the requirements of the Australian Standard, and to the customer's specification.

Fantech has links with the Australasian Institute of Dangerous Goods Consultants. Institute members are qualified to assess the correct fan for hazardous locations and can help customers to ensure Fantech has the right information when placing an order.

Motors handling dusts or fine fibres are not covered in this article.